The term ‘workplace safety’ has

more significance in the industrial organizations than in the traditional

offices. According to most of the business owners, a manufacturing association,

encompassing all the storerooms, passageways and service rooms must be kept

clean, well-ordered as well as in a sanitary condition. The floors should be

dried and drainage must be present, wherever wet procedures are performed. A

large number of industries all across the globe have taken some essential

steps, in order to offer the labors with a safe and secure working environment

as well as prevent all sorts of mishaps.

In the following discussion, we

are going to explore one of the vital steps that are adopted by most of the

leading industrial sectors.

Safety Measures

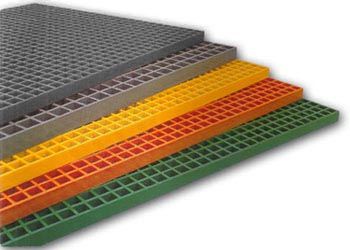

Perhaps the most common

protective measure taken up by colossal industries of the world is installing grating

in the

workplaces. It could be defined as a collection of parallel, elongated and

identical elements that are spaced regularly. Although many kinds of materials

could be used for the fabrication of this framework, most of the associations

prefer using GRP or glass-reinforced plastic. Questions might arise as to why

the GRP stands to be beneficial over all the other construction resources

available. Well, this is because they have some essential and distinctive

features. Let us take a good look at them as they are mentioned below in brief.

Benefits of GRP Grating Systems

• They possess a phenomenal anti-slip property and thus, could be successfully used in oily or wet environments. The fundamental construction and entrenched grit combine together to offer a non-slippery surface with maximum impact.

• GRP frameworks have the ability to resist itself from caustic industrial chemicals and other environmental factors. Thus, they stand to be a relevant alternative to steel, carbon, wood, aluminum and other traditional supplies. It does not matter if the element is exposed to continuous spills, splashes, submersions, gases or fumes; GRP would effortlessly outperform all the other mediums.

• GRP is resistant to fire and heat. So, a framework made of this material could optimally perform in conditions with flames and high temperatures.

• As GRP is non-magnetic, it could be used in all kinds of sensitive environments, where the intrinsic magnetic properties of metals would stand to be unsuitable.

• GRP is noted for having high impact resistance, which means it would be able to retain its normal shape, even if its subjected to intense pressure.

• The non-sparking properties of GRP make it ideal

for environments, where combustible gases could be found. Using other metals

could cause an explosion and lead to unnecessary accidents.

From the aforementioned points, it could be concluded that industries could have safety walkways only if it has GRP flooring structures and frames.

As for example, if you consider utilizing grating products in the workplace that would definitely ameliorate the environment. Similarly, Pedestrian structures can be a very practical alternative for you. Just have a look how these structures can offer some astounding advantages for your industry.

• It would better the structural integrity of the concrete structures; that’s the reason there would be hardly any chance for to the workers to encounter certain mishaps.

• FRP materials, being lightweight in nature, can suit each and every industry as well. It hardly matters whether your business is big, small or a moderate one. Even more, you can use such structures in conveyor walkways, mineral process plants, marine and coastal applications and particularly in areas of high traffic.

• Moreover, FRP materials can be available in so many designs and structures that it can suit almost every space in your workplace.

On the more, this kind of cost-effective grating system would perfectly suit wet work platforms like stairways, walkways, and other fixed platforms. Furthermore, it can be used idyllically for public walkways like boardwalks, jetties, and parks or reserves. As a result, anyone can have a safe access to those structures. Another product that can be blessing for you and all in industrial sectors is Fiberglass ladders.

It is known to all that ladders are something that needs to be used for multipurpose. There would be hardly any working place or residential place where this item is not essential. But when it comes to using the item in some adverse environments or some chemical or power plants the ladder must need some extra features as well. Let us explore a few super qualities of FRP ladders.

• Corrosion resistant

• Cost Effectiveness

• Structurally strong

• Lightweight

• Impact resistant

• Low electrical and thermal conductivity

These features have got a further boost when manufacturers have made it very much easy to install. You can also use them in chemical plants; in fact, the anti-corrosive nature of this kind of ladders would be just compatible for any kind of harmful chemicals as well. Workers use Fiberglass ladders at ease in power plants for its unique features.